Thermodynamic analysis of a new ocean thermal energy conversion regenerative cycle

-

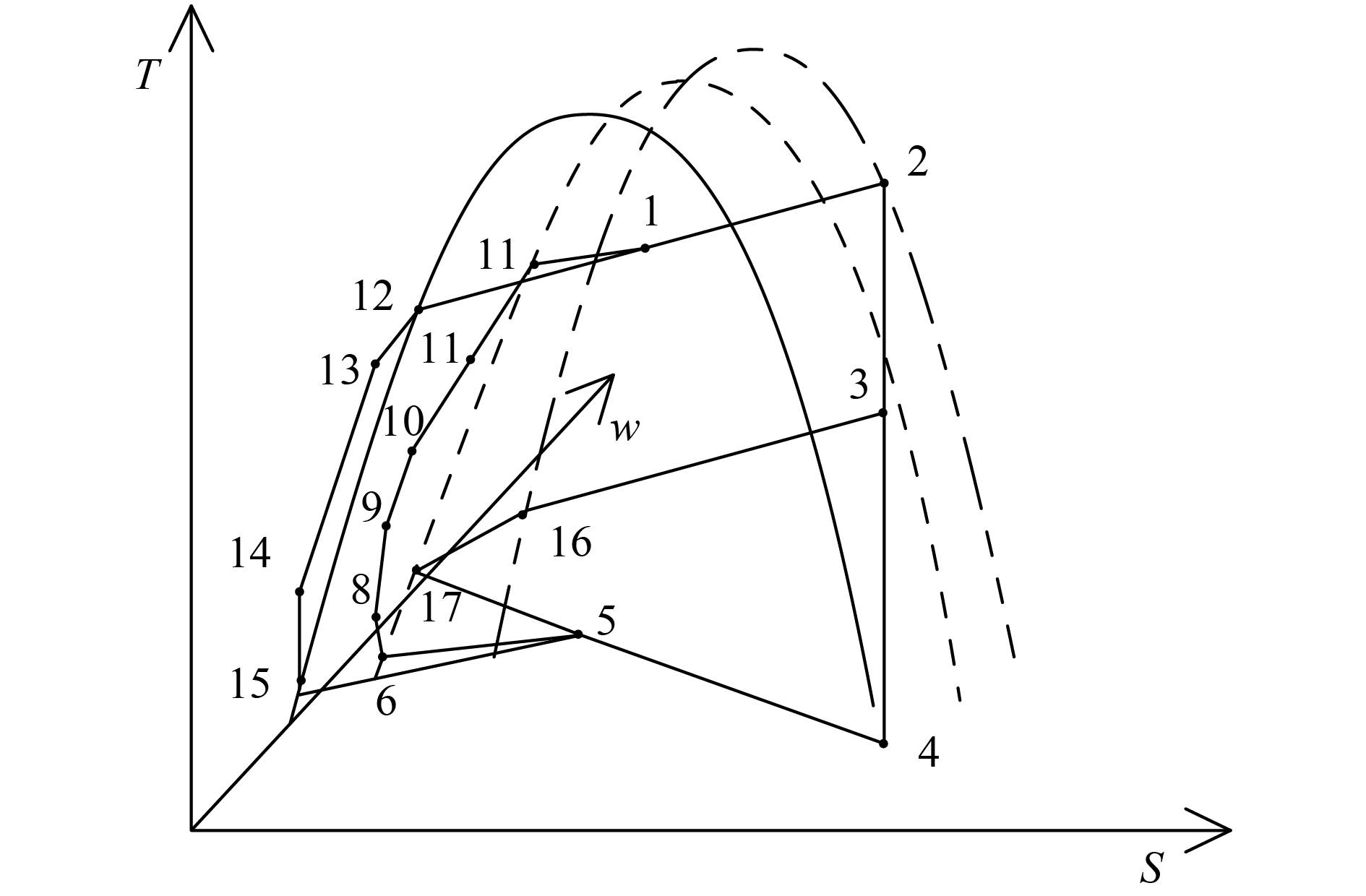

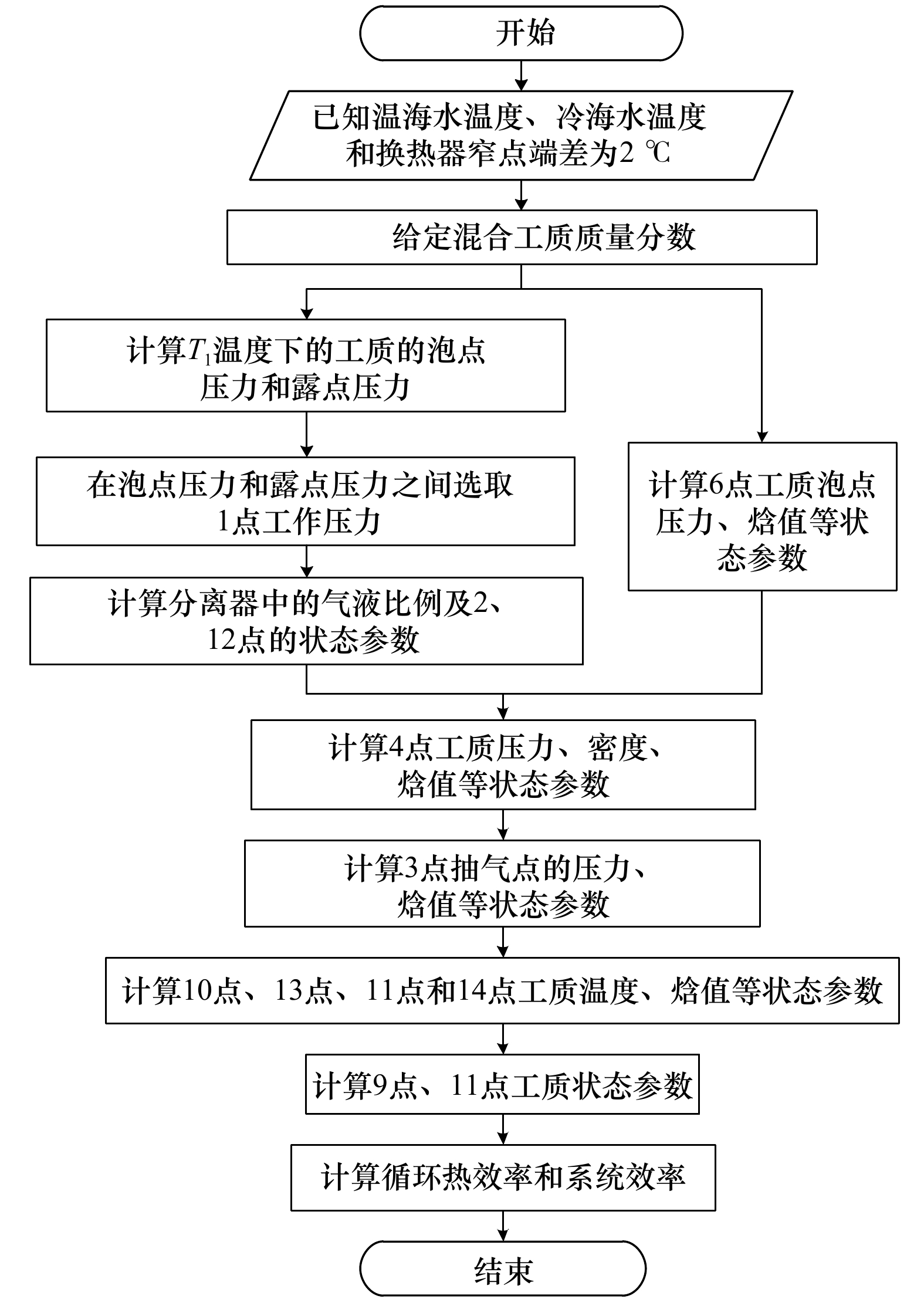

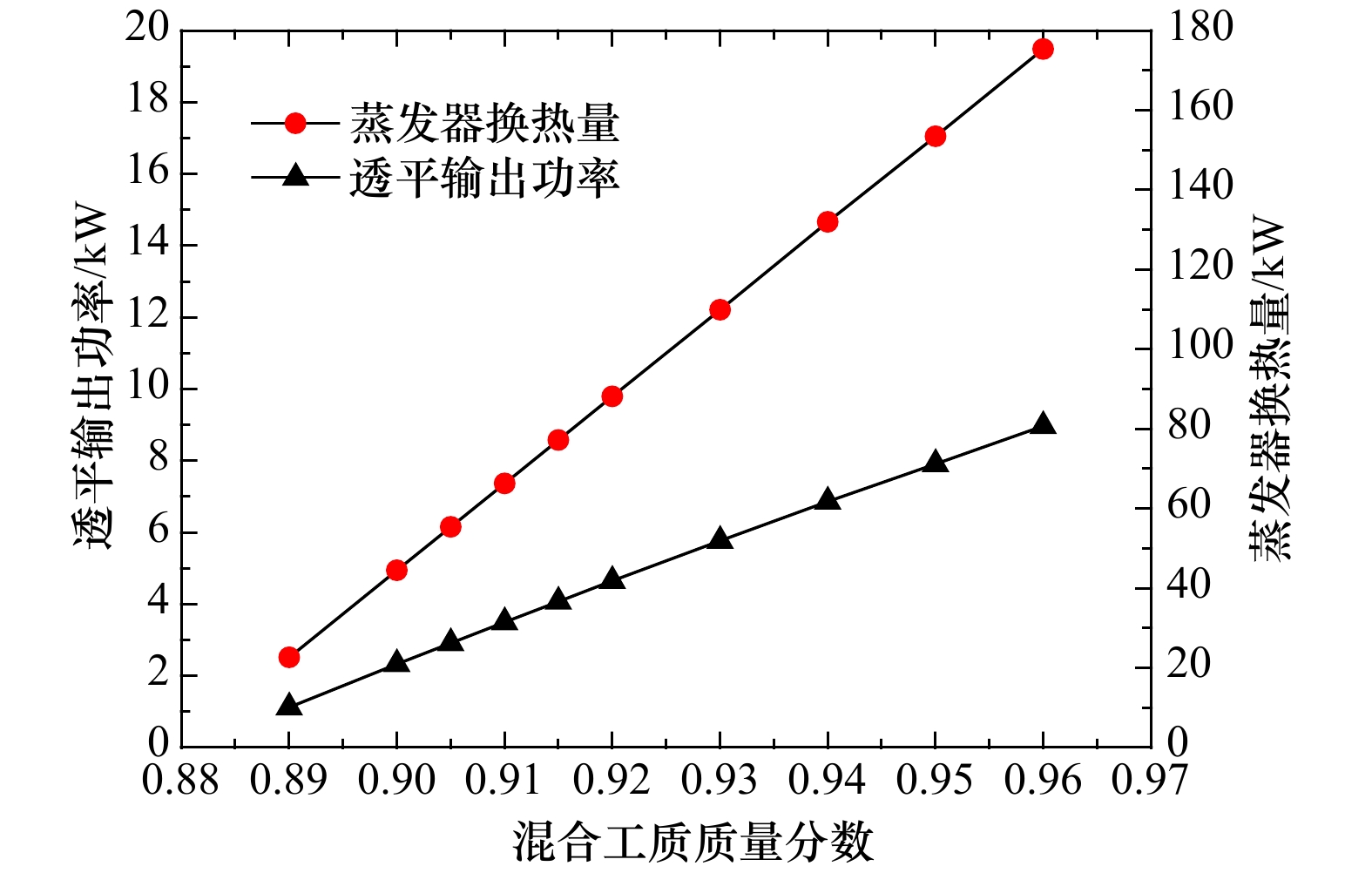

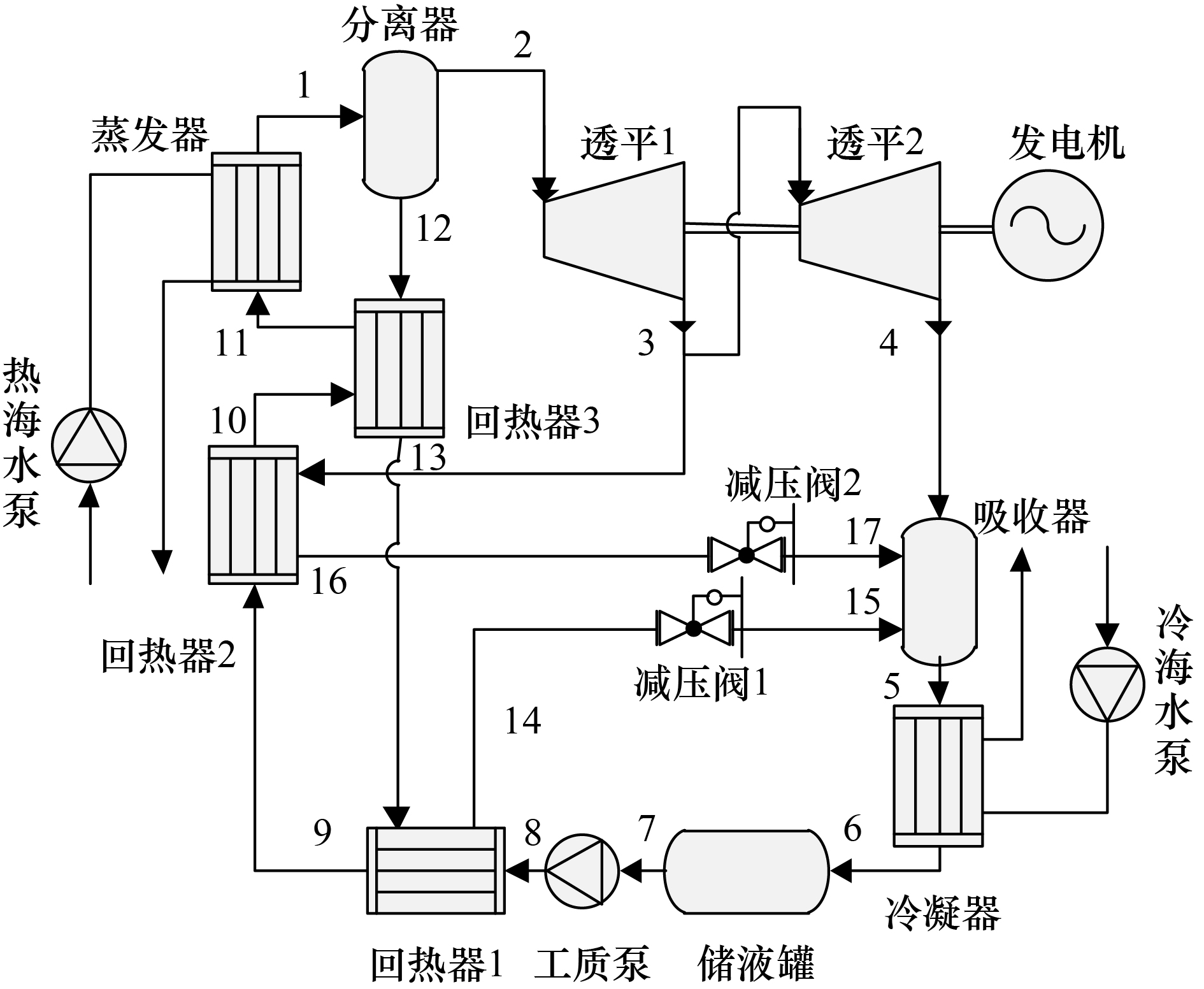

摘要: 针对海洋温差能可利用温差小,利用效率低的问题,本文提出了一种采用非共沸混合工质的新型海洋温差能回热循环,并基于热力学定律对提出的热力循环进行热力学分析。选取蒸发压力、工质的质量分数作为变量,对提出的热力循环进行热力学分析研究。研究结果表明:以工质质量分数为变量时,循环热效率和系统净输出随蒸发压力的增加先增大后减小,系统热效率在工质质量分数为0.91时取得最大值5.28%,净输出功在浓度为0.96时取得最大值3.83 kW。以蒸发压力为变量时,循环热效率和系统净输出随工质质量分数的增大先增大后减小,系统热效率在蒸发压力为0.595 MPa时取得最大值5.26%,净输出功在压力为0.58 MPa时取得最大值3.57 kW。在相同运行控制参数下与Uehara循环、Yoon循环进行对比,提出的循环系统热效率最佳。提出的热力循环系统分析结果可对提高海洋温差能利用效率提供理论依据和参考。Abstract: In view of the problems of small available temperature difference and low utilization efficiency of ocean thermal energy conversion (OTEC). A new thermodynamic cycle of OTEC using non-azeotropic mixed working fluid is proposed. Based on the laws of thermodynamics, the thermodynamic analysis of the proposed thermodynamic cycle is carried out. Evaporation pressure, mass fraction of working fluid, evaporation temperature and condensation temperature are selected as influencing variables to study the proposed thermodynamic cycle. The results show that when the working fluid mass fraction is selected as a variable, with the evaporation pressure increases the cycle thermal efficiency and the net output of system increase first and then decrease. The system thermal efficiency achieves a maximum value of 5.28% when the working fluid mass fraction is 0.91. The maximum value of 3.83 kW is obtained when the mass fraction of the working fluid is 0.96. When the evaporation pressure is selected as the variable, the cycle thermal efficiency and the net output of the system increase first and then decrease with the mass fraction of the working medium increases. The cycle thermal efficiency achieves a maximum value of 5.26% when the evaporating pressure is 0.595 MPa, and the net output work obtains a maximum value of 3.57 kW when the evaporating pressure is 0.58 MPa. Compared with Uehara cycle and Yoon cycle under the same operating conditions, the proposed cycle system has the highest thermal efficiency. The analysis results of the proposed thermal cycle system can provide a theoretical basis and reference for improving the utilization efficiency of OTEC.

-

表 1 循环系统的理论分析初始条件组合

Tab. 1 Initial conditions for theoretical analysis of circulatory system

工况 温海水温度T/℃ 冷海水温度T/℃ 工质质量分数w 蒸发压力 p/MPa 1 26 5 0.90 0.55 2 26 5 0.90 0.56 3 26 5 0.90 0.57 4 26 5 0.90 0.58 5 26 5 0.90 0.59 6 26 5 0.90 0.595 7 26 5 0.90 0.60 8 26 5 0.90 0.604 9 26 5 0.89 0.60 10 26 5 0.90 0.60 11 26 5 0.905 0.60 12 26 5 0.91 0.60 13 26 5 0.915 0.60 14 26 5 0.92 0.60 15 26 5 0.93 0.60 16 26 5 0.94 0.60 17 26 5 0.95 0.60 18 26 5 0.96 0.60 19 26 5 0.97 0.60 20 26 5 0.98 0.60 表 2 文献[12]所述工况下提出的循环各节点参数

Tab. 2 Parameters of the proposed cycle under the conditions described in reference [12]

节点 温度

T/K压力

p/MPa氨质量

分数w焓值h/kJ·kg−1 熵值S/ kJ·kg−1K−1 质量流量比/

kg·kg−11 299.20 0.85 0.90 856.69 3.40 1.00 2 299.20 0.85 0.99 1 641.8 5.91 0.43 3 286.33 0.67 0.99 1 610.3 5.91 0.01 4 276.48 0.48 0.99 1 570.2 5.91 0.99 5 281.46 0.48 0.90 767.31 3.20 1.00 6 279.15 0.48 0.90 258.21 1.38 1.00 7 279.15 0.48 0.90 258.21 1.38 1.00 8 279.21 0.85 0.90 258.76 1.38 1.00 9 282.17 0.85 0.90 272.61 1.43 1.00 10 284.33 0.85 0.90 282.75 1.46 1.00 11 291.75 0.85 0.90 317.79 1.58 1.00 12 299.20 0.85 0.83 275.96 1.54 0.57 13 286.33 0.85 0.83 215.00 1.33 0.57 14 281.21 0.85 0.83 190.90 1.24 0.57 表 3 文献[17]所述工况下Uehara循环、Yoon循环和新循环的参数比较

Tab. 3 Comparison of parameters of Uehara cycle, Yoon cycle and proposed cycle under the conditions described in reference [17]

变量 循环形式 Uehara循环 Yoon循环 新循环 冷凝器出口蒸气质量分数 1 0.95 1 温海水进口温度/℃ 26 26 26 冷海水进口温度/℃ 5 5 5 蒸发器出口端差/℃ 2 2 2 装机功率/kW 20 20 20 透平效率 0.8 0.8 0.8 泵效率 0.65 0.65 0.65 工质质量流量/kg·h−1 2 810 2 800 6 723 温海水质量流量/kg·h−1 232 800 230 500 209 400 冷海水质量流量/kg·h−1 118 100 116 400 104 700 工质侧压降/kPa 10 10 10 海水侧压降/kPa 50 50 50 工质种类 H2O+NH3 NH3 H2O+NH3 工质浓度/kg·kg−1 0.955 1 0.91 系统效率/% 2.379 2.401 2.532 -

[1] Khan N, Kalair A, Abas N, et al. Review of ocean tidal, wave and thermal energy technologies[J]. Renewable and Sustainable Energy Reviews, 2017, 72: 590−604. doi: 10.1016/j.rser.2017.01.079 [2] Hammar L, Ehnberg J, Mavume A, et al. Renewable ocean energy in the Western Indian Ocean[J]. Renewable and Sustainable Energy Reviews, 2012, 16(7): 4938−4950. doi: 10.1016/j.rser.2012.04.026 [3] 丁亮, 李卉, 史学增. 基于太阳能再热循环的海洋温差发电系统性能分析与改进[J]. 中国造船, 2019, 60(S1): 171−178.Ding Liang, Li Hui, Shi Xuezeng. Performance analysis and improvement of solar energy reheated CC-OTEC system[J]. Shipbuilding of China, 2019, 60(S1): 171−178. [4] 刘伟民, 麻常雷, 陈凤云, 等. 海洋可再生能源开发利用与技术进展[J]. 海洋科学进展, 2018, 36(1): 1−18.Liu Weimin, Ma Changlei, Chen Fengyun, et al. Exploitation and technical progress of marine renewable energy[J]. Advances in Marine Science, 2018, 36(1): 1−18. [5] Jung J Y, Lee H S, Kim H J, et al. Thermoeconomic analysis of an ocean thermal energy conversion plant[J]. Renewable Energy, 2016, 86: 1086−1094. doi: 10.1016/j.renene.2015.09.031 [6] Ikegami Y, Yasunaga T, Morisaki T. Ocean thermal energy conversion using double-stage Rankine cycle[J]. Journal of Marine Science and Engineering, 2018, 6(1): 21. doi: 10.3390/jmse6010021 [7] Chen Fengyun, Liu Lei, Peng Jingping, et al. Theoretical and experimental research on the thermal performance of ocean thermal energy conversion system using the Rankine cycle mode[J]. Energy, 2019, 183: 497−503. doi: 10.1016/j.energy.2019.04.008 [8] 黄靖伦, 王辉涛, 喻智锋, 等. 非共沸混合工质有机朗肯循环余热回收系统的热力性能[J]. 中国水运, 2018, 18(8): 229−230.Huang Jinglun, Wang Huitao, Yu Zhifeng, et al. Thermodynamic performance of non-azeotropic mixed working fluid organic Rankine cycle waste heat recovery system[J]. China Water Transport, 2018, 18(8): 229−230. [9] Aydin H, Lee H S, Kim H J, et al. Off-design performance analysis of a closed-cycle ocean thermal energy conversion system with solar thermal preheating and superheating[J]. Renewable Energy, 2014, 72: 154−163. doi: 10.1016/j.renene.2014.07.001 [10] Kusuda E, Morisaki T, Ikegami Y. Performance test of double-stage Rankine cycle experimental plant for OTEC[J]. Procedia Engineering, 2015, 105: 713−718. doi: 10.1016/j.proeng.2015.05.061 [11] Kalina A. Combined-cycle system with novel bottoming cycle[J]. Journal of Engineering for Gas Turbines and Power, 1984, 106(4): 737−742. doi: 10.1115/1.3239632 [12] Uehara H, Ikegami Y, Nishida T. Performance analysis of OTEC system using a cycle with absorption and extraction processes[J]. Transactions of the Japan Society of Mechanical Engineers, 1998, 64(624): 2750−2755. doi: 10.1299/kikaib.64.2750 [13] Matsuda Y, Yoshitake T, Sugi T, et al. Construction of a static model for power generation of OTEC plant using uehara cycle based on experimental data[J]. Journal of Marine Science and Engineering, 2018, 6(1): 18−31. doi: 10.3390/jmse6010018 [14] Ikegami Y, Yasunaga T, Harada H. Performance experiments on ocean thermal energy conversion system using the uehara cycle[J]. Bulletin of the Society of Sea Water Science Japan, 2006, 60(1): 32−38. [15] Yuan Han, Mei Ning, Yang Shuai, et al. Theoretical investigation of a power cycle using ammonia-water as working fluid[J]. Advanced Materials Research, 2014, 875−877: 1837−1841. doi: 10.4028/www.scientific.net/AMR.875-877.1837 [16] Yuan Han, Mei Ning, Zhou Peilin. Performance analysis of an absorption power cycle for ocean thermal energy conversion[J]. Energy Conversion and Management, 2014, 87: 199−207. doi: 10.1016/j.enconman.2014.07.015 [17] Yoon J I, Son C H, Baek S M, et al. Performance characteristics of a high-efficiency R717 OTEC power cycle[J]. Applied Thermal Engineering, 2014, 72(2): 304−308. doi: 10.1016/j.applthermaleng.2014.05.103 -

下载:

下载: